600 years ago the old masters would bind up pieces of silver or gold, place pallets of solder at stategic locations, then put the entire piece into a hot kiln.

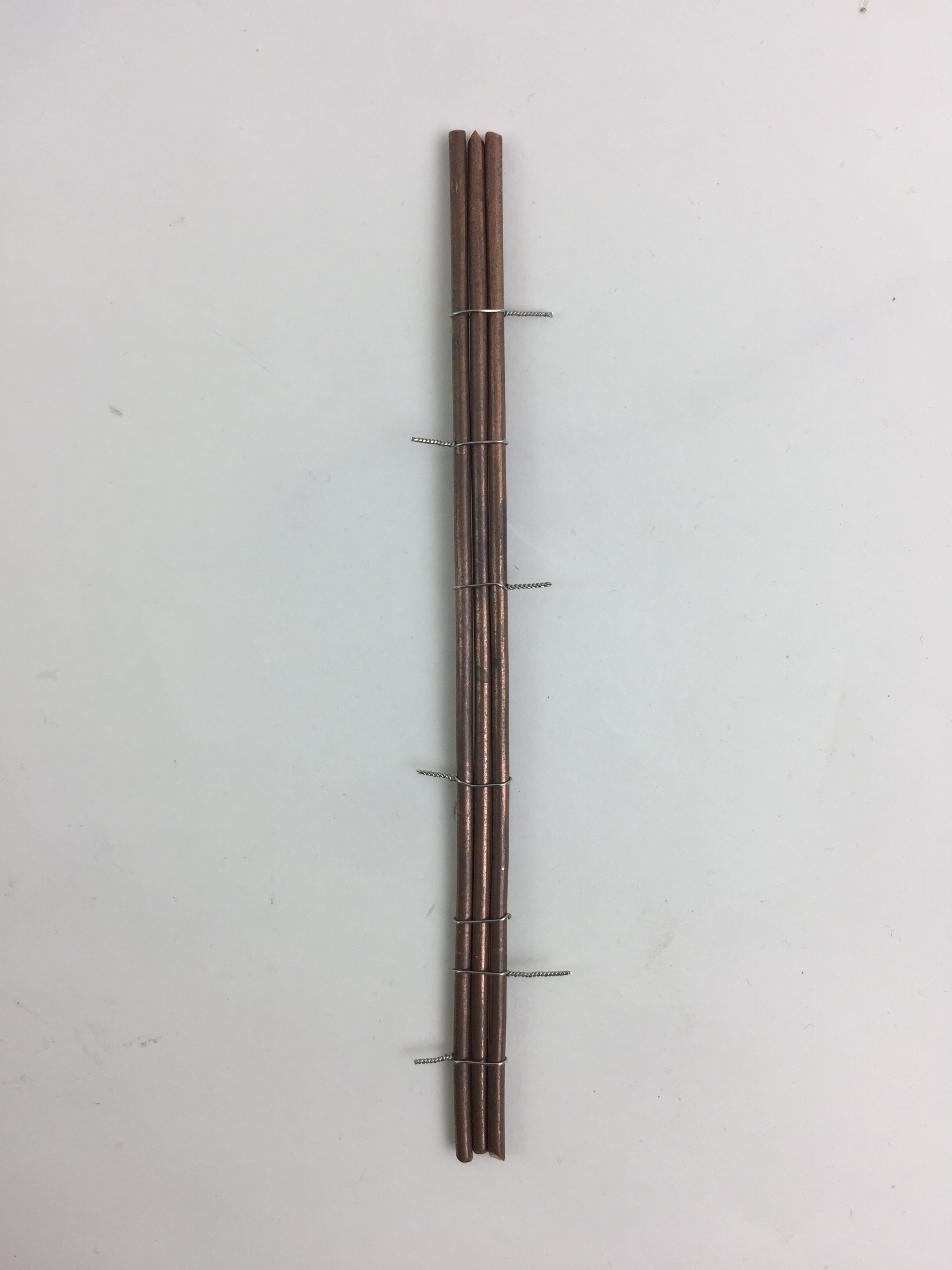

Here we have 3 strands of 10 gauge copper wire bound up with steel wire.

Numerous soft silver pallions are placed in the stream between the wires. Copper solder would be easier, but its brittle and will crack under forging. Also, very little solder is needed. The intention however is to create a visible silver channel between the wires.

A beautiful red flame patina us achieved. The color of the flame patina is affected by atmospheric conditions. Tonight is a low pressure front coming in. It produces a deep red. I am not sure if we will be able to maintain this color throughout successive firings as we forge the bracelet

Let's mill it down a bit to flatten the wire.

One pass gives the piece some authority.

Also use the mill to put a dip and a taper at the ends. The milling has extended the metal out to 6 1/2 inches, the desired length.

I filed the ends then begin forming it around this cool bracelet mandrel. I'll work it up to the smallest wrung the back it up at least one size

And this is what I come up with. Now it needs to be signed, dated and sealed.